Food Processing & Packaging

We serve a variety of industries, including fresh and frozen fruits and vegetables, pet food, bakery, snacks, pasta and noodles, and seafood.

Are you ready to enhance the efficiency and safety at your food processing facility?

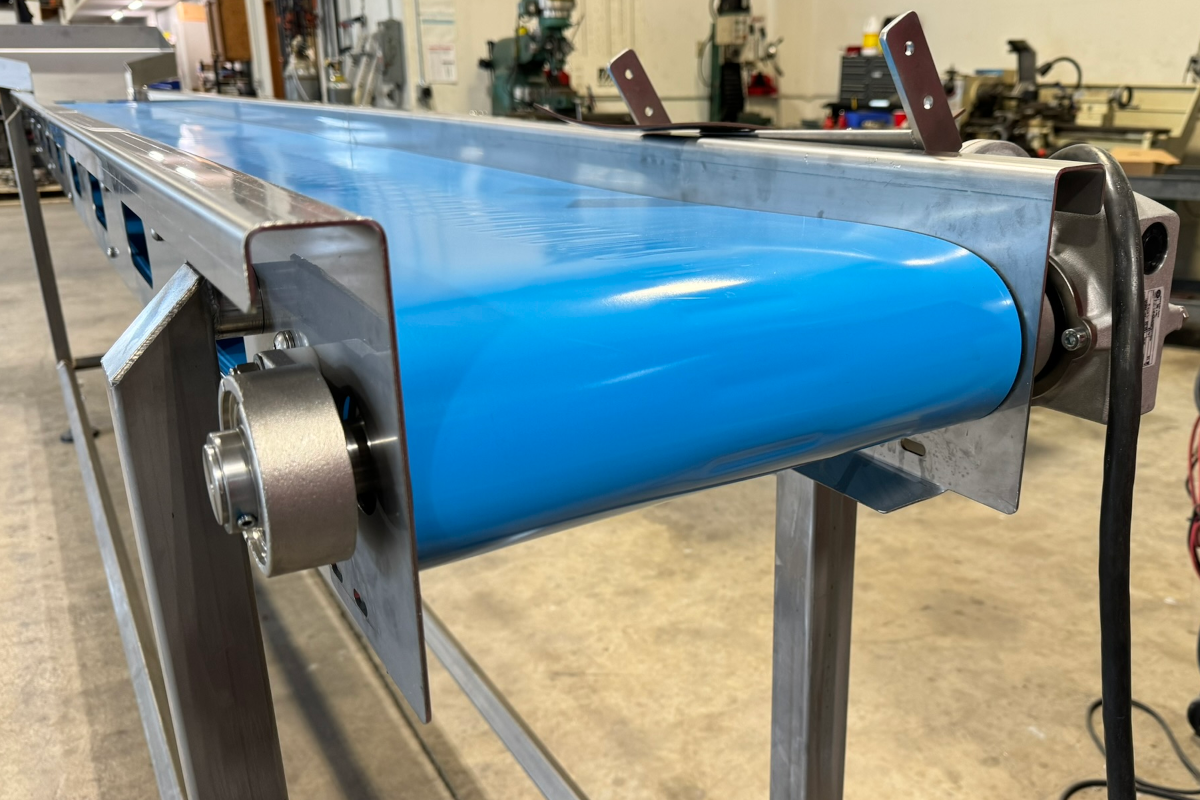

At Primo Fabrication, we specialize in designing and manufacturing state-of-the-art equipment tailored for the food industry, prioritizing sanitary design and safety.

Our experienced team collaborates with you to create customized solutions that meet your unique operational requirements, ensuring optimal performance and compliance with stringent sanitary standards. With our innovative designs, you can minimize contamination risks and boost productivity while benefiting from easy maintenance. From consultation to installation and ongoing support, we’re committed to your success.

Contact us today to discover how our cutting-edge equipment can elevate your food processing operations!